-23 %

MECHANIC LVH900-RY RED UV SOLDER MASK - 10CC

Id: 3299

- Item Code/Product Code: LVH 900-RY

- Weight: 0.02kg

₹155.00

₹200.00

Ex Tax: ₹155.00

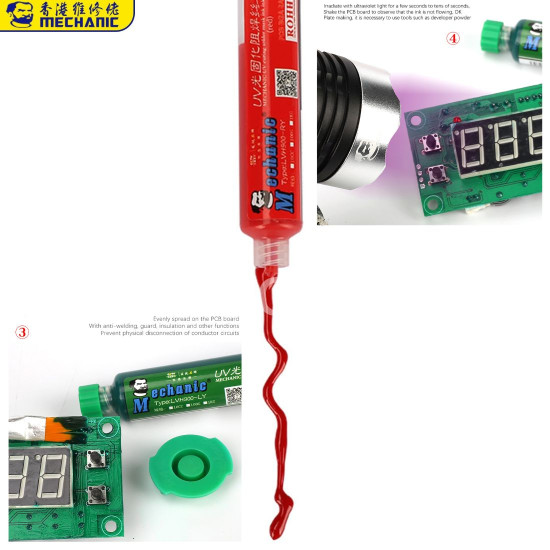

MECHANIC UV CURING SOLDER MASK INK [RED]

Features:

- High Quality

- 10ml UV red paint

- Insulates printed circuit board against shorting and arcing.

- This paint is used to protect PCB traces from corrosion, moisture.

- It is also used for repairing PCB after soldering, rework.

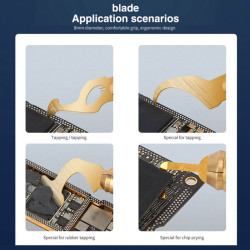

Usage:

- Apply paint on your PCB.

- Spread it on the PCB with covering the transparent mask film.

- Expose it under UV light ( or sun ) for a few minutes.

- Wash away the extra paint by gasoline or oil base solvent.

- Masking Paste

( 1 x Mechanic 10ML Red Uv Curing Solder Mask Ink )

What is the ink oil of the solder mask?

- Solder mask insulating paint on printed circuit board.

- A solder-resistant ink oil of liquid photos is an acrylic oligomer.

- As a protective layer, it is applied to the circuit board and substrate on which the printed circuit board is not to be soldered or used as a weld resistant.

- The purpose is to protect the formed line model for a long time.

- Essential materials for PCB board repair, one of the most commonly used materials for printed boards.

Industrial Applications:

- Prevent physical disconnection of the conductor circuit.

- Welding only in parts that need to be welded to avoid welding waste.

- It has a high insulation and allows you to increase the density of the circuit.

- Reduce the copper contamination of the welding trough, it can shield the copper foil on the board from the air to prevent the oxidation of the copper foil.

- Anti-corrosion and Anti-oxidation (prevents swelling and corrosion of the insulation due to external environmental factors such as dust and moisture.)

- In the welding process, the short circuit caused by the bridge is prevented. (Avoid soldering spreading along copper foil or causing a short circuit during the production process.)

Instructions:

- Substrate treatment: acid treatment, brush washing, drying.

- Screen printing: use the screen version of 36T ~ 51T.

- Pre-bake: the temperature is 75 ± 2 ° c, the time is 40 ~ 50 minutes, the hot air circulation is dry.

- Exposure: 300-500mj/cm2.

- Imaging: Imaging solution: 0.9-1.1%, sodium carbonate, temperature: 28-30 °C, spray pressure: 1.5-3.0 kg/cm2.

- Post-cooking: the temperature is 150 ° C, the time is 60 minutes, the polymerization of the hot air circulation.

- Due to the special nature of the material, the welding mask oil does not dry naturally. UV curing is required.

- The internal temperature should be controlled at 20-28 degC and the humidity RH30-60 % is the best working environment.

- To clean the substrate error, it is recommended to use industrial alcohol or industrial detergent.

Precautions:

- Use only with adequate ventilation.

- The product contains organic solvent. Avoid repeated contact with the skin. If the product comes on your skin, dry it with alcohol and rinse it thoroughly with water.

- In order to be cautious, in the operation, the smoke released from the solvent during operation should be optimized as much as possible, AND the tissues of the skin and bone membranes should not be contacted for too long. Avoid repeated steam breathing.

- Avoid contacting your eyes.

- Keep away from children.

Warm up the tip:

- If you like this item, put it in your wish list, if you like my store, put it in your store list.

- We provide a big order big discount, if you have any questions, please contact you for free, thank you very much!