-550x550.jpg)

-550x550.jpg)

-550x550.jpg)

-550x550.jpg)

-550x550.jpg)

-550x550.jpg)

-550x550.jpg)

-80x80.jpg)

-80x80.jpg)

-80x80.jpg)

-80x80.jpg)

-80x80.jpg)

-80x80.jpg)

-80x80.jpg)

Id: 4244

- Item Code/Product Code: SW-5S

- Weight: 0.30kg

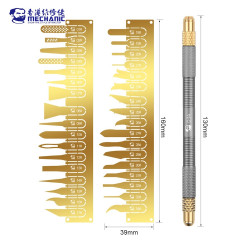

Mechanic SW-5S Tin Dragging Needle for Micro Soldering

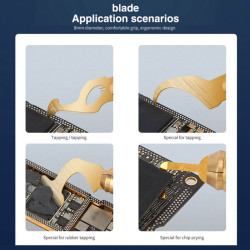

Why Pros Choose the Mechanic SW-5S Tin Dragging Needle Built for precision rework, the Mechanic SW-5S Tin Dragging Needle gives technicians fine, repeatable control over molten solder on tight-pitch ICs and micro pads. Instead of fighting solder bridges after drag soldering, guide and distribute tin exactly where you want it—reducing rework, protecting pads, and improving joint consistency. The heat-resistant, corrosion-resistant needle and anti-slip handle deliver confident manipulation under the microscope, whether you’re correcting bridges, shaping fillets, or tidying pads on mobile logic boards. Tested across common leaded and lead-free workflows, the SW-5S is a simple, reliable tool that elevates finish quality and saves bench time.

Features

- Surgical-Grade Stainless Steel Tip: The ultra-fine, durable tip allows for precise solder manipulation without scratching or damaging delicate PCB pads.

- Master Solder Bridging: Effortlessly separates and removes unwanted solder connections between pins on CPUs, PMICs, and other integrated circuits.

- Ergonomic, Anti-Static Handle: Provides a secure, comfortable grip for steady control during prolonged use, while safely dissipating static to protect sensitive components.

- Optimized for BGA Pad Cleaning: Perfect for evenly distributing solder paste and clearing residual tin from pads, ensuring a clean and reliable connection for reballing.

Specification

| Parameter | Details |

|---|---|

| Model | Mechanic SW-5S |

| Type | Tin Dragging Needle |

| Material | High-strength alloy |

| Application | IC soldering, PCB rework, mobile repair |

| Heat Resistance | High temperature durability |

| Usability | Reusable, long service life |

Benefits / Usage

- Ensures precise solder alignment and tin flow

- Reduces solder bridging on fine-pitch ICs

- Extends tool life with heat-resistant design

- Increases repair accuracy and efficiency

- Trusted choice for mobile phone repair professionals

How it’s used

- Prep: Clean area and apply quality flux to the target pins/pads.

- Form Bead: Create a small molten solder bead with your iron or hot air.

- Guide: Touch the SW-5S needle to the bead and gently drag along the pin row to distribute solder evenly.

- Fix Bridges: Feather the needle between bridged pins with added flux; use controlled heat to split and wick excess.

- Finish: Remove heat, let cool, clean with IPA, and inspect under magnification for uniform fillets and no shorts.

- Tips: Keep pressure light, refresh flux as needed, and work parallel to pads to avoid lifting.

Package Content

- 1 × Mechanic SW-5S Tin Dragging Needle

FAQs

- Q1: What is the main use of the SW-5S Tin Dragging Needle?

- A: It is mainly used for precision tin dragging, correcting solder bridges, and fine soldering work on ICs and PCBs.

- Q2: Is it suitable for mobile phone repair?

- A: Yes, it is specifically designed for mobile logic board and micro soldering repairs.

- Q3: Is the needle reusable?

- A: Yes, it is made of durable alloy material, making it reusable and long-lasting.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-250x250.jpg)